Maintaining safety features involves ongoing costs like inspections, parts replacements, and software updates that can add up quickly if not managed proactively. Wear and tear or system upgrades may lead to unexpected expenses, and neglecting regular maintenance increases the risk of costly failures or accidents. To avoid surprises, you need a clear maintenance plan, budget for future upgrades, and practice regular checks. Continuing ahead will reveal how to keep those hidden costs in check and safeguard your investments.

Key Takeaways

- Regular maintenance, including inspections and updates, prevents costly repairs and safety violations caused by neglected safety features.

- Upgrading safety systems requires hardware, software, and compatibility adjustments that can incur unexpected expenses over time.

- Hidden costs like professional installation, system downtime, and ongoing software licensing can significantly increase total ownership costs.

- Failure to plan for future replacements and technological updates may lead to expensive emergency repairs or system failures.

- Implementing proactive maintenance strategies and detailed record-keeping helps avoid surprise costs and ensures long-term safety compliance.

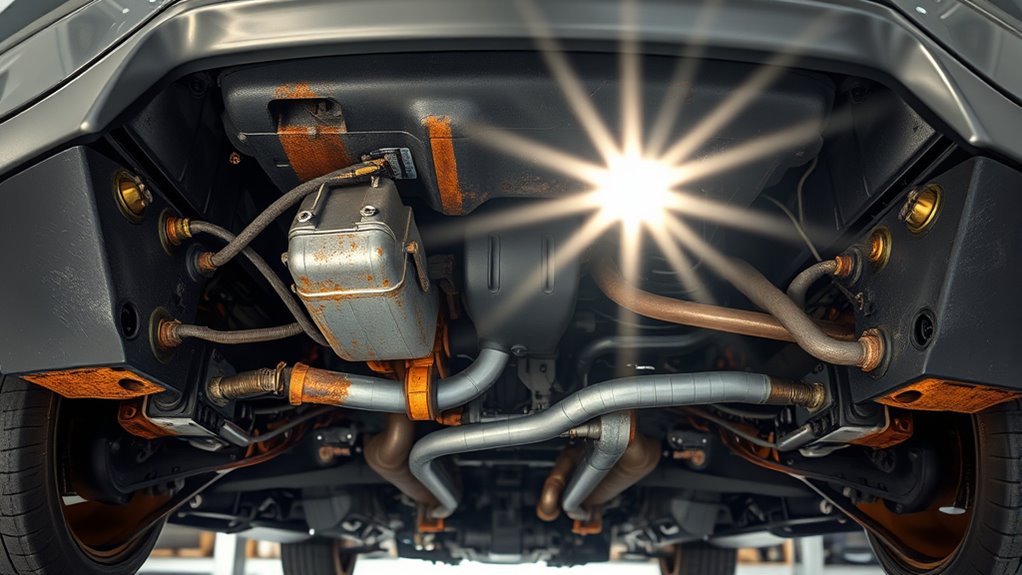

The Hidden Expenses of Regular Maintenance for Safety Systems

Have you ever considered how the routine upkeep of safety systems can quietly drain your budget? Regular maintenance is essential for safety compliance, but it often comes with hidden costs. Frequent inspections, parts replacement, and system updates add up over time, making maintenance less budget-friendly than you might think. To manage these expenses, focus on cost-effective upgrades that improve system reliability without overspending. Prioritizing preventive maintenance can also reduce costly repairs later on. Remember, neglecting regular upkeep can lead to safety violations, fines, or even accidents, which are far more expensive. Staying proactive with maintenance ensures safety compliance while keeping expenses predictable. By carefully planning and investing in efficient safety upgrades, you can avoid unnecessary costs and maintain a safe environment without breaking the bank. Incorporating preventive maintenance strategies can help identify potential issues early, saving money and enhancing safety in the long run.

Repair Costs That Catch You Off Guard

Unexpected emergency repairs can suddenly drain your wallet when safety features fail. You might also face high costs for specialized parts that aren’t readily available. Plus, these systems often require frequent maintenance, adding to the surprise expenses. Incorporating organized storage solutions can help prevent clutter that may hinder maintenance routines and reduce the risk of safety feature malfunctions.

Unexpected Emergency Repairs

You might think your vehicle is well-equipped to handle everyday driving, but safety features can sometimes lead to costly emergency repairs you didn’t see coming. An unexpected emergency, like a sudden breakdown, can strike without warning, leaving you stranded and facing hefty repair bills. These issues often stem from complex safety systems that, if malfunctioning or misinterpreted, cause critical components to fail unexpectedly. For instance, sensors or electronic modules might trigger false alerts, prompting sudden repairs you weren’t prepared for. While safety features aim to protect you, they can also increase the risk of unforeseen emergencies. Staying vigilant, maintaining regular inspections, and understanding how these systems work can help you avoid surprise repairs, keeping your vehicle reliable and your costs manageable. Additionally, understanding the cost implications of safety features can help you budget for potential repairs before they happen.

Specialized Part Expenses

Specialized safety components often come with hefty price tags that can catch you off guard during repairs. These specialized parts, such as advanced sensors or custom-made safety modules, typically have higher component pricing compared to standard parts. When a safety feature fails, replacing these components isn’t just costly—it can also lead to longer repair times due to limited availability. You might find that the expense of these specialized parts strains your budget more than expected. To avoid surprises, always research the typical costs associated with your vehicle’s safety features and consider whether repairs are covered under warranty. Being aware of the potential for high component pricing helps you plan ahead, avoiding unexpected financial shocks when safety parts need replacement. Additionally, understanding AI vulnerabilities in safety systems emphasizes the importance of regular maintenance and updates to ensure ongoing reliability.

Frequent Maintenance Needs

While high costs for specialized safety components can catch you off guard, frequent maintenance needs for safety systems can also lead to surprising expenses. Safety feature longevity depends on proper maintenance scheduling, but some components demand regular attention that can add up quickly. If neglected, these systems may become unreliable or fail prematurely. To avoid unexpected costs, stay proactive with maintenance. Regular inspections for wear and tear, replacement of sensors and actuators, updating software and firmware, calibration to guarantee accurate operation, scheduled part replacements based on manufacturer guidelines, and monitoring air quality sensors are essential to ensure ongoing performance and prevent costly repairs.

The Impact of Wear and Tear on Safety Components

As your safety components wear down over time, they can deteriorate faster than expected, leading to accelerated deterioration. This means you might face more frequent repairs and replacements than initially planned. Consequently, maintenance costs can quickly escalate, catching you off guard financially. Recognizing the importance of preventive maintenance can help extend the lifespan of safety features and reduce unexpected expenses.

Accelerated Component Deterioration

Though safety features are designed to protect you, they can also accelerate the wear and tear on critical components. Constant activation and frequent use lead to component fatigue, causing parts to weaken faster. Over time, this results in increased part degradation, which can compromise safety. You might notice:

- Reduced lifespan of sensors and actuators

- Faster deterioration of hydraulic and electronic systems

- Increased chances of micro-cracks forming

- Accelerated wear of mechanical linkages

- Higher risk of sudden failures due to fatigue-induced cracks

These issues mean safety components may degrade prematurely, demanding more frequent replacements and repairs. Ignoring this accelerated deterioration can lead to costly repairs and reduced reliability in critical moments. Staying aware of these effects helps you plan preventive measures and avoid unexpected breakdowns.

Maintenance Cost Escalation

The increased wear and tear on safety components caused by frequent activation directly lead to rising maintenance costs. As safety features activate more often, you face higher expenses for repairs and replacements. Conducting a cost benefit analysis helps determine whether the safety benefits justify these costs, ensuring safety compliance without overspending. To manage escalating costs, consider the following: Special Occasions which emphasize the importance of planned maintenance and timely inspections to prevent unnecessary expenses.

| Activation Frequency | Maintenance Cost | Impact on Safety Compliance |

|---|---|---|

| High | Increased | Ensuring ongoing safety |

| Moderate | Manageable | Balance between cost and safety |

| Low | Minimal | Cost-effective safety measures |

Costs Associated With Upgrading and Replacing Safety Features

Upgrading and replacing safety features can be a significant expense that often catches consumers off guard. The costs involved go beyond initial purchase and include upgrading costs and replacement expenses as technology advances or features become outdated. These costs can add up quickly, especially if safety systems require specialized installation or calibration. You might face unexpected charges for parts, labor, or compatibility issues. Additionally, maintaining compatibility with newer technology can require ongoing software updates, which may incur additional costs over time.

- Hardware or software updates to current safety systems

- Professional installation fees

- Compatibility adjustments with existing components

- Temporary vehicle downtime during upgrades

- Future replacement expenses for outdated features

These costs highlight the importance of planning ahead and understanding the long-term financial implications of safety upgrades. Proper budgeting can prevent surprises and ensure your safety features stay effective without draining your wallet.

How Neglecting Maintenance Can Lead to Costly Failures

Neglecting regular maintenance on safety features can lead to costly failures that compromise your vehicle’s protection. When safety systems aren’t properly maintained, you risk mechanical breakdowns, reduced effectiveness, and potential safety hazards. Failing to prioritize safety training can result in improper handling, increasing failure risk. Additionally, neglecting maintenance may put you out of regulatory compliance, leading to fines or legal issues. To visualize, consider the following:

| Maintenance Issue | Potential Consequence |

|---|---|

| Ignored safety training | Mishandling safety features |

| Skipped inspections | Undetected system wear or damage |

| Delayed repairs | System failure during critical moments |

| Poor record-keeping | Non-compliance penalties |

| Lack of updates | Outdated safety protocols |

Regular upkeep ensures safety features perform reliably, avoiding costly failures down the line. Understanding park operating hours can help in planning your maintenance schedules efficiently.

Budgeting for Long-Term Safety System Upkeep

Effective budgeting is crucial to guarantee your safety systems stay dependable over the long term. You need to consider ongoing costs that might not be immediately obvious, like parts replacement and system updates. Conducting a thorough safety audit helps identify vulnerabilities and prioritize maintenance needs, ensuring efficient resource allocation. A solid cost benefit analysis evaluates whether investing in upgrades now saves money later by preventing failures. Regularly review maintenance schedules and adjust budgets accordingly, keeping future expenses predictable. Remember, neglecting long-term upkeep can lead to costly repairs or safety lapses, undermining your safety goals. Planning ahead with detailed budgets empowers you to maintain safety features effectively, avoiding unexpected expenses and maximizing system longevity. Additionally, understanding the concept of creative practice can inspire innovative approaches to maintenance planning, ensuring your safety systems are both effective and adaptable over time.

Practical Strategies to Minimize Maintenance-Related Expenses

Implementing practical strategies can considerably reduce maintenance-related expenses for your safety systems. Focus on cost-effective solutions by choosing durable, high-quality components that need less frequent repairs. Regular preventative measures, such as scheduled inspections and timely replacements, prevent costly breakdowns and extend system lifespan. Train staff to perform basic upkeep, which minimizes reliance on outside contractors and reduces labor costs. Keep detailed maintenance records to identify recurring issues early, enabling targeted fixes rather than reactive, expensive repairs. Adopt technology like remote monitoring to detect problems before they escalate. By integrating these preventative measures into your routine, you can optimize safety system performance while controlling expenses, ensuring long-term reliability without unnecessary financial strain.

Frequently Asked Questions

How Do Hidden Maintenance Costs Vary Between Different Safety Systems?

You’ll find that hidden maintenance costs vary based on system compatibility and warranty coverage. Systems with complex compatibility requirements may require specialized parts, increasing expenses. Without proper warranty coverage, repairs can become costly, especially after the warranty expires. Regular maintenance is essential to prevent unexpected costs, so choose safety systems with robust warranties and verify compatibility to minimize hidden expenses over time.

What Are the Most Overlooked Expenses in Safety Feature Upkeep?

Picture safety expenses as an iceberg, with hidden costs lurking beneath the surface. You often overlook ongoing safety training and emergency preparedness, which are essential for effective safety feature upkeep. These overlooked expenses can lead to costly mistakes or equipment failure. Regularly investing in training and preparedness guarantees your safety systems work flawlessly, reducing unforeseen costs and keeping your team protected. Don’t let hidden expenses sink your safety efforts—stay vigilant and proactive.

How Can Scheduling Impact Long-Term Safety Maintenance Costs?

Scheduling plays a vital role in controlling long-term safety maintenance costs. By establishing regular maintenance scheduling, you can prevent costly repairs and guarantee safety features operate effectively. Incorporate safety cost planning into your schedule to avoid unexpected expenses. Proactive maintenance minimizes downtime and extends the lifespan of safety systems. Consistent scheduling ultimately saves money, keeps safety measures reliable, and reduces the risk of costly emergencies down the line.

Are There Cost-Effective Alternatives to Frequent Safety Upgrades?

You might wonder if there are cost-effective solutions that sidestep constant safety upgrade expenses. The answer is yes—consider safety upgrade alternatives like implementing proactive maintenance, utilizing durable, adaptable safety equipment, or investing in advanced technology that reduces frequent upgrades. These strategies not only save money over time but also enhance safety. By choosing smarter safety solutions, you keep costs manageable without compromising protection, ensuring a safer environment with fewer surprises.

What Are the Key Signs Indicating Safety System Failure Risks?

You should watch for signs like inconsistent system alerts, delayed responses, or unusual noises, which suggest safety system failure risks. Regular safety system upgrades and proper maintenance scheduling help prevent these issues. If you notice these signs, don’t delay; addressing them promptly ensures your safety features function correctly and reduces the likelihood of costly repairs or failures down the line. Stay vigilant to keep your safety systems reliable.

Conclusion

By neglecting maintenance, you risk costly repairs and safety failures. Yet, investing in regular upkeep might seem like an expense, but it’s an investment in peace of mind. The true cost isn’t just dollars spent but the safety and trust you protect. Prioritize proactive maintenance; it’s the difference between avoiding unexpected expenses and facing unforeseen disasters. Remember, the lowest upfront cost can often lead to the highest long-term price.