To guarantee your tip-over and overheat sensors work reliably, choose the right types for your environment—mechanical or electronic—and calibrate them regularly. Proper placement at manufacturer-recommended heights and angles is vital to prevent false alarms. Make certain sensors are securely mounted and protected from dust, vibrations, or environmental interference. Consistent maintenance, testing, and correct integration into your safety system help avoid false alarms and ensure long-term performance. Keep these tips in mind, and you’ll better understand how to optimize your sensors for safety.

Key Takeaways

- Proper calibration and threshold settings prevent false alarms and ensure sensors respond accurately to hazards.

- Correct placement and secure mounting at manufacturer-recommended heights optimize detection and reduce environmental interference.

- Regular maintenance, calibration, and performance tracking maintain long-term sensor reliability and system effectiveness.

- Avoid environmental factors like heat sources, drafts, or electromagnetic interference that can cause false triggers.

- Ensure sensor compatibility and seamless integration with safety systems for real-time monitoring and reliable operation.

Understanding the Different Types of Tip Over and Overheat Sensors

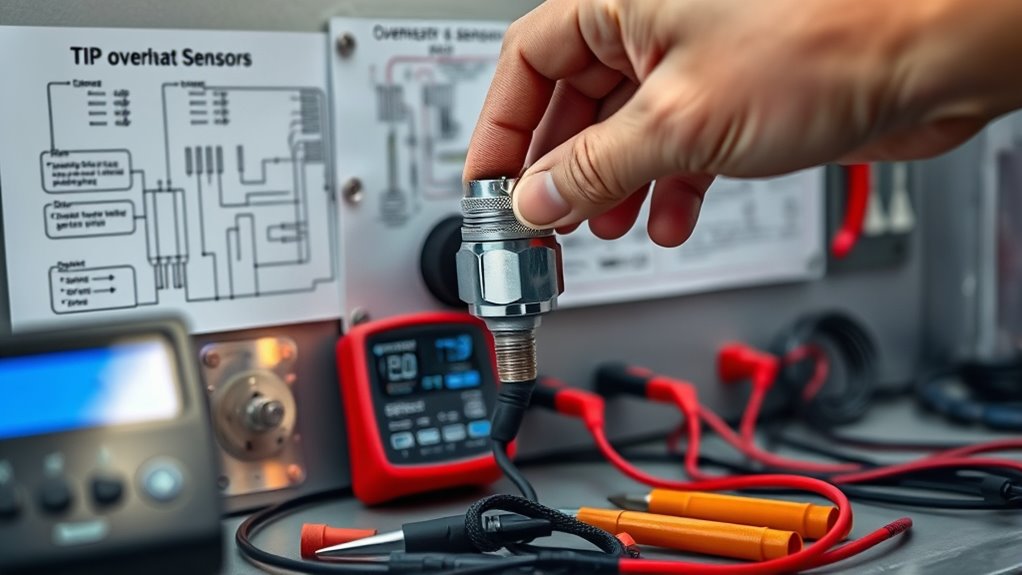

To effectively protect your equipment, it’s important to understand the different types of tip-over and overheat sensors available. These sensors vary in design and function, with calibration being vital for accuracy. Proper sensor calibration ensures that alarm thresholds are set correctly, preventing false alarms or missed detections. Some sensors use mechanical switches that trigger at a specific tilt angle, while others rely on electronic accelerometers that detect movement more precisely. Overheat sensors typically employ temperature-sensitive elements, such as thermistors or thermocouples, which must be calibrated regularly to maintain reliable alarm thresholds. Knowing how each sensor type responds to environmental changes helps you select the right technology and set appropriate calibration parameters, guaranteeing your safety systems activate reliably when needed. Additionally, understanding sensor calibration techniques used in Honda tuning can help optimize sensor performance for various conditions.

Proper Placement and Mounting Strategies for Optimal Performance

Proper placement and mounting are essential for sensors to perform accurately and reliably. To achieve this, you must consider proper installation techniques that guarantee consistent sensor calibration over time. Position sensors where they can detect tip overs or overheating early, avoiding obstructions or false triggers. Mount them at recommended heights and angles specified by the manufacturer, as incorrect positioning can compromise detection accuracy. Secure mounting prevents sensor shift or damage, maintaining calibration and responsiveness. Regularly inspect and verify placement to assure it aligns with environmental conditions. By following precise installation techniques, you maximize sensor lifespan and performance, reducing false alarms and missed detections. Understanding performance tuning laws can also help in selecting optimal sensor settings for different vehicle types and conditions. Ultimately, correct placement and mounting are key to ensuring your sensors operate at their best and provide reliable safety coverage.

Selecting the Right Sensors Based on Environment and Equipment

Choosing the right sensors depends heavily on the specific environment and equipment you’ll be monitoring. For environments with high vibrations or dust, select sensors with robust sensor calibration to maintain accuracy over time. If you need continuous monitoring, opt for sensors that support data logging, enabling you to track temperature or tilt trends and identify patterns. Consider whether your equipment operates indoors or outdoors, as this influences sensor durability and waterproofing. For sensitive or hazardous areas, choose sensors with quick response times and appropriate certifications. Matching sensor type and specifications to your environment ensures reliable detection and reduces false alarms. Properly calibrated sensors with integrated data logging help you maintain system performance and facilitate maintenance planning. Additionally, understanding relationship dynamics can improve how you interpret sensor data, especially in complex environments where multiple factors influence readings.

Common Pitfalls and How to Avoid False Alarms

To prevent false alarms, you need to focus on proper sensor placement and avoid environmental interference. If sensors are poorly positioned or exposed to dust, vibrations, or extreme temperatures, they may trigger unnecessary alerts. Regular testing guarantees your system works accurately and helps identify potential issues before they cause problems. Incorporating automation technologies can further optimize sensor performance and reduce the risk of false alarms.

Proper Sensor Placement

While installing overheat and tip-over sensors, you need to be mindful of their placement to prevent false alarms. Follow the manufacturer’s installation guidelines carefully to ensure proper sensor calibration. Place sensors in locations that accurately reflect the environment’s typical conditions, avoiding spots near heat sources or drafts. For tip-over sensors, mount them on stable surfaces where accidental bumps won’t trigger false alarms, but also where they can detect genuine tilting. Position sensors at recommended heights and angles to optimize sensitivity. Regularly check their calibration to maintain accuracy. Proper placement minimizes false alarms and ensures reliable detection. Remember, a well-placed sensor is your first line of defense against both safety hazards and unnecessary disruptions. Additionally, understanding how juice cleansing impacts health can help inform safer and more effective sensor installation environments.

Avoid Environmental Interference

Have you considered how environmental factors can cause false alarms with your sensors? Factors like temperature fluctuations, humidity, dust, or nearby electromagnetic interference can disrupt sensor accuracy if not properly addressed. To prevent this, verify your sensors are correctly calibrated for the environment they’re in. Proper sensor calibration helps distinguish between genuine triggers and environmental noise, reducing false alarms. Avoid placing sensors near sources of environmental interference, such as vents, heaters, or electronics that emit electromagnetic signals. Regularly check and adjust calibration settings, especially if conditions change or after maintenance. Additionally, understanding AI Bifurcation can help you anticipate how evolving technology might impact sensor functionality and security. By understanding and controlling environmental factors, you improve sensor reliability and prevent unnecessary alarms, ensuring your tip-over and overheat detection systems remain accurate and effective.

Regular System Testing

Regular system testing is vital to guarantee your tip-over and overheat sensors work correctly over time. You need to regularly check sensor calibration to guarantee accuracy, as miscalibrated sensors can cause false alarms or missed detections. During testing, verify that alarm thresholds are correctly set and respond appropriately to actual hazards. Avoid neglecting this step, as outdated settings can lead to unnecessary shutdowns or dangerous failures. Keep detailed records of each test to track sensor performance and calibration adjustments. Regular testing also helps identify potential environmental factors that may interfere with sensor operation. By staying vigilant and proactive, you minimize false alarms, guarantee reliable protection, and extend your sensor system’s lifespan. Proper testing is your best defense against costly oversights.

Maintenance and Testing to Ensure Long-Term Reliability

To guarantee your tip-over and overheat sensors remain reliable over time, consistent maintenance and testing are essential. Regular sensor calibration ensures that detection accuracy stays sharp, preventing false alarms or missed hazards. Check and adjust alarm thresholds periodically to match changing conditions and system requirements. Inspect sensors for dust, debris, or damage that could impair performance. Test alarms after calibration to confirm they trigger correctly at set thresholds. Document all maintenance activities to track sensor performance over time. Maintaining proper calibration and alarm threshold settings keeps your safety system effective and responsive. Proper calibration is crucial for long-term reliability and can help prevent sensor drift that might compromise safety. Skipping these steps risks sensor drift, false alarms, or failures during critical moments. Stay proactive with routine checks, and your sensors will deliver long-term reliability and peace of mind.

Integrating Sensors Into Your Overall Safety and Monitoring System

Integrating tip-over and overheat sensors into your overall safety and monitoring system guarantees that all components work seamlessly to protect people and property. To do this effectively, ensure sensor compatibility with your existing setup, including alarms, control panels, and automation systems. Proper data integration allows real-time monitoring and accurate alerts, minimizing false positives or missed incidents. Use compatible communication protocols and data formats to streamline information flow. Regularly update software and firmware to maintain integration efficiency. Additionally, selecting sensors with robust environmental resistance ensures durability and reliable performance in various conditions. By coordinating sensors with your broader safety infrastructure, you create a unified system that responds quickly and reliably to hazards. This integration not only enhances safety but also simplifies management and troubleshooting, giving you peace of mind knowing your system is working cohesively.

Frequently Asked Questions

How Do Sensor Sensitivities Impact False Alarm Rates?

Sensor sensitivities directly impact false alarm rates; if they’re too sensitive, you’ll experience frequent false alarms, causing unnecessary disruptions. Proper sensor calibration helps strike a balance, reducing false alarm occurrences while maintaining safety. Focus on false alarm mitigation by adjusting sensitivity settings carefully, ensuring the sensors respond accurately to real hazards without overreacting to minor movements or temperature changes. Regular calibration and testing are key to optimizing performance and minimizing false alarms.

What Are the Best Practices for Sensor Wiring Safety?

You should guarantee proper sensor wiring safety by using high-quality, durable wiring that withstands environmental factors. Always follow manufacturer guidelines for correct sensor calibration to prevent false alarms caused by wiring issues. Secure connections firmly to avoid disconnections or shorts, and protect wiring from physical damage. Regularly inspect and replace worn or damaged wiring to maintain system integrity, ensuring your sensors function accurately and safely over time.

Can Sensors Be Integrated With Existing Alarms Easily?

Yes, sensors can be integrated with your existing alarms easily if you guarantee proper sensor calibration and check alarm compatibility. First, verify that your alarm system supports the sensor’s communication protocol. Then, calibrate the sensors correctly to ensure accurate detection. Most modern systems allow straightforward integration, but consulting the manufacturer’s guidelines helps avoid compatibility issues. Proper setup guarantees reliable alerts and seamless integration with your current alarm system.

How Do Environmental Factors Affect Sensor Lifespan?

Environmental factors can notably affect sensor durability, with exposure to extreme temperatures reducing lifespan by up to 30%. You should regularly check environmental calibration to guarantee sensors function correctly. High humidity, dust, and vibration accelerate wear, so protecting sensors with proper enclosures and maintenance extends their operational life. By understanding how these factors impact your sensors, you can optimize their performance and avoid costly replacements.

Are There Industry Standards for Sensor Installation?

Yes, industry standards for sensor installation exist, emphasizing proper placement and adherence to installation guidelines. You should guarantee sensors are calibrated correctly during installation to maintain accuracy and reliability. Following these standards helps prevent false alarms and extends sensor lifespan. Always refer to manufacturer instructions and relevant codes to guarantee your sensors are installed correctly, ensuring ideal performance and safety in your environment.

Conclusion

By mastering the art of tip over and overheat sensors, you’re building a safety net that catches trouble before it strikes. Think of these sensors as vigilant guardians, silently standing watch over your equipment. When properly placed, maintained, and integrated, they become the unsung heroes of your safety system—turning potential chaos into calm. Embrace their power, and let them be your first line of defense amid the unpredictable dance of machinery.