To guarantee tip over and overheat sensors work reliably, you must place them correctly, following manufacturer guidance to avoid false alarms. Regular testing, calibration, and using quality components are vital for accuracy and safety. Be mindful of environmental factors like dust or temperature swings, and document performance over time to catch issues early. Proper training and staying updated on new standards help prevent failures—continue exploring these essential rules to keep your system dependable.

Key Takeaways

- Proper placement at appropriate heights and angles ensures sensors detect tipping or overheating accurately.

- Regular calibration and cleaning prevent false alarms caused by dust, debris, and environmental factors.

- Understand each sensor’s range and environmental limitations to avoid missed detections or false triggers.

- Secure wiring and correct installation practices reduce connection issues and false alarms.

- Consistent maintenance, testing, and documentation improve sensor reliability and system safety over time.

Proper Placement Is Critical for Accurate Detection

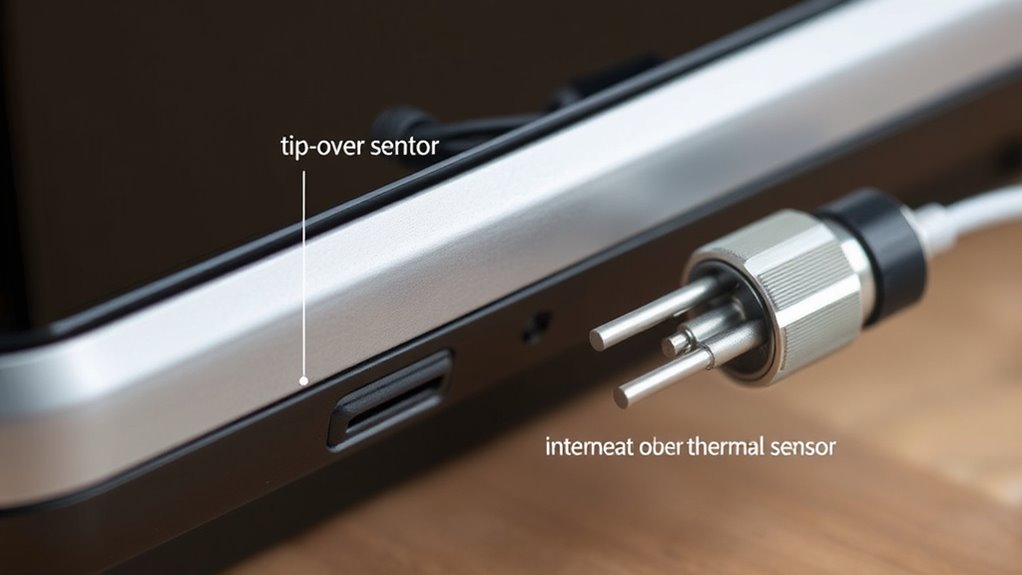

Proper placement of tip over and overheat sensors is crucial to guarantee they detect issues accurately. Proper sensor placement ensures that sensors respond promptly, catching potential problems early. When installing sensors, you should consider the manufacturer’s guidelines for ideal sensor placement, avoiding areas prone to false alarms or damage. Accurate calibration procedures are also essential; they help fine-tune sensors to recognize normal operation versus dangerous conditions. Misplaced sensors can lead to delayed alerts or false triggers, putting your equipment at risk. Take the time to carefully position sensors in areas where they can monitor temperature and tilt effectively. Regularly review and adjust their placement and calibration procedures to maintain reliable detection and ensure safety. Proper sensor placement is key to effective safety monitoring, and understanding the proper installation techniques can significantly improve their performance.

Understand the Difference Between Tip Over and Overheat Sensors

Have you ever wondered how tip over and overheat sensors differ in their function and significance? Tip over sensors detect when an appliance, like a water heater, tilts or falls, triggering an immediate shutdown to prevent accidents. Overheat sensors, on the other hand, monitor temperature levels, activating alarms or shutting down when temperatures exceed safe limits. Proper sensor calibration ensures each sensor responds accurately, avoiding false alarms or missed detections. Alarm integration is vital here, as overheat sensors often trigger visual or audible alerts to warn you of potential hazards. Understanding these differences helps you maintain safety and compliance. Remember, each sensor plays a distinct role, so knowing their specific functions ensures you respond appropriately and keep your appliances running safely. Additionally, the contrast ratio significantly impacts how well images are rendered, especially in dark scenes, which is crucial for a home cinema setup.

Regular Testing and Calibration Are Essential

To guarantee your tip over and overheat sensors function correctly, regular testing and calibration are vital. You must follow consistent maintenance schedules to ensure sensors respond accurately when needed. Neglecting this can lead to dangerous malfunctions, risking property and lives. Proper sensor calibration keeps devices sensitive enough to detect hazards early, preventing disasters. Schedule testing intervals based on manufacturer recommendations and environmental conditions. Use the table below to visualize the importance:

| Frequency | Action | Consequence |

|---|---|---|

| Monthly | Perform sensor calibration | Ensures reliable detection |

| Quarterly | Test sensor response | Prevents false alarms |

| Annually | Full system maintenance | Maintains safety standards |

| As needed | Address calibration drift | Keeps sensors in peak condition |

Stay diligent—your safety depends on it. Ensuring that your sensors are calibrated correctly also aligns with the importance of content creation in maintaining effective safety measures, as accurate data is essential for timely hazard detection.

Avoid Common Installation Mistakes

When installing tip over and overheat sensors, you need to focus on proper mounting techniques to guarantee reliable operation. Make sure your wiring practices are correct to prevent connection issues or false alarms. Avoid common mistakes that can compromise safety and sensor performance. Additionally, selecting the appropriate sensor type for your specific application ensures optimal durability and function over time.

Proper Mounting Techniques

Proper mounting is vital to guarantee your sensors function correctly and safely. Incorrect placement can cause false alarms or missed detections. To ensure maximum performance, follow these installation guidelines:

- Mount sensors at the recommended height and angle, considering the device’s calibration requirements.

- Secure sensors firmly to prevent shifting or vibrations that could affect sensor calibration.

- Avoid mounting near heat sources, vents, or areas prone to dust, which can impair sensor accuracy.

- Verify that the sensor’s line of sight is unobstructed for reliable detection.

- Supporting proper installation can help minimize false alarms and ensure consistent operation.

Correct Wiring Practices

Ensuring correct wiring practices is key to reliable sensor operation and safety. Start by consulting wiring diagrams to confirm proper connections. Use high-quality, appropriately rated cables and avoid shortcuts that can cause loose or faulty connections. Proper wiring ensures accurate sensor calibration, preventing false triggers or missed detections. Always follow manufacturer instructions to wire tip-over and overheat sensors correctly. Double-check that power and signal lines are clearly identified and properly insulated. Avoid common installation mistakes like crossing wires or using incompatible connectors. Secure all connections tightly to prevent vibrations or disconnections. Document your wiring setup, making future troubleshooting easier. Correct wiring practices guarantee the sensor functions as intended, reducing risks and ensuring long-term reliability. Additionally, understanding bedroom design principles can help you organize your equipment effectively, minimizing clutter and potential hazards.

Use Quality Components to Prevent False Triggers

Using high-quality components is essential to prevent false triggers in tip-over and overheat sensors. When you choose reliable parts, you improve sensor calibration and guarantee consistent performance. Quality components offer better durability, reducing the risk of malfunctions over time. To maximize effectiveness, consider these key points:

Using premium components ensures reliable sensor performance and long-term durability.

- Select sensors with proven durability to withstand environmental stresses.

- Use components with precise specifications to maintain accurate sensor calibration.

- Opt for reputable brands that assure consistent quality.

- Regularly verify component integrity to prevent false triggers caused by wear and tear.

Keep Sensors Clean and Free of Debris

Keeping sensors clean and free of debris is essential for maintaining their accurate operation. Dirt or dust can interfere with sensor calibration, causing false triggers or missed detections. Regular debris removal ensures your sensors respond reliably. To optimize performance, clean sensors gently with a soft cloth and avoid harsh chemicals. Use the following table to understand which cleaning method suits your sensor type:

| Sensor Type | Recommended Cleaning Method |

|---|---|

| Tip-over sensors | Soft brush and compressed air |

| Overheat sensors | Damp cloth with mild detergent |

| Both | Regular inspection, debris removal, calibration check |

| Sensitive areas | Consult manufacturer guidelines |

Staying vigilant with cleaning and debris removal keeps your sensors functioning accurately and prolongs their lifespan. Additionally, ensuring sensors are free of obstructions enhances overall air purifier performance.

Know the Limitations of Your Sensor System

You need to understand your sensor’s range limits so it can detect issues accurately. Environmental factors like dust, moisture, or extreme temperatures can also affect sensor performance. Knowing these limitations helps you trust your system and avoid false alarms or missed signals. Additionally, being aware of paint sprayer specifications ensures you select compatible equipment that operates within the sensor’s effective range.

Sensor Range Constraints

Have you ever wondered why some sensors fail to detect a hazard even when it seems close? Sensor range constraints can be the culprit. Your sensor’s effectiveness depends heavily on proper calibration and placement accuracy. If it’s not calibrated correctly, it might not recognize hazards within its designated range. Similarly, poor placement can cause blind spots or false readings. Keep these points in mind:

- Range limitations vary between sensor models.

- Calibration ensures sensors respond accurately within their range.

- Placement accuracy affects detection zones.

- Overextending sensor range can lead to false alarms or missed hazards.

- Understanding sensor limitations helps in optimizing system performance.

Understanding these constraints helps you maintain reliable performance and avoid surprises. Always verify your sensor calibration and ensure correct placement to maximize detection accuracy within its specified range.

Environmental Influences Impact

Environmental factors can considerably impact sensor performance, often limiting their ability to detect hazards accurately. Humidity interference can cause false readings or delay warnings by affecting sensor sensitivity. Electromagnetic influence, such as nearby motors or radio waves, can also disrupt sensor signals, leading to inaccuracies. Recognizing these limitations helps you maintain reliable safety systems.

| Environmental Factor | Effect |

|---|---|

| Humidity interference | False alarms, delayed detection |

| Electromagnetic influence | Signal disruption, inaccurate readings |

| Temperature fluctuations | Sensor malfunction or drift |

Integrate Sensors Into a Comprehensive Safety Strategy

Integrating sensors into a thorough safety strategy guarantees that tip-over and overheat risks are continuously monitored and effectively managed. To do this, you should:

- Regularly perform sensor calibration to ensure accuracy and reliable readings.

- Integrate alarms seamlessly with your existing safety systems to trigger quick responses.

- Establish clear protocols for responding to sensor alerts, minimizing delays.

- Maintain a detailed record of sensor performance and calibration schedules for ongoing dependability.

- Incorporate essential oils for safety to help create a calming environment that promotes alertness and reduces stress during emergency responses.

Be Aware of Environmental Factors That Affect Performance

Since environmental conditions can vary widely, understanding how factors like humidity effects, temperature fluctuations, dust, and vibration impact the performance of tip-over and overheat sensors is essential. High humidity can cause moisture buildup, leading to false triggers or sensor corrosion over time. Temperature swings may affect sensor sensitivity, making them less dependable. Dust accumulation can obstruct sensor components, reducing accuracy, while vibrations can cause false alarms or sensor fatigue. Electromagnetic interference (EMI) from nearby electrical devices can disrupt sensor signals, causing unreliable readings or failures. To guarantee peak performance, regularly inspect and maintain sensors, minimize exposure to EMI sources, and control humidity levels whenever possible. Being aware of these environmental factors helps prevent false alarms and ensures your safety system functions correctly.

Document and Track Sensor Performance Over Time

You should regularly monitor sensor trends to catch any signs of performance decline early. Keep detailed records of environmental conditions during inspections to identify potential correlations. Tracking these factors over time helps guarantee your sensors remain reliable and effective.

Monitor Sensor Trends

How can you guarantee your sensors remain reliable over time? The key is to monitor sensor trends consistently. First, regularly review sensor calibration records to ensure accuracy. Second, track performance data to identify deviations that may signal drift. Third, perform scheduled sensor maintenance, including cleaning and component checks, to prevent malfunction. Fourth, compare current readings against baseline performance to catch early signs of decline. By systematically documenting these trends, you can act proactively, maintaining sensor reliability. This approach helps you spot issues before they escalate, ensuring your tip-over and overheat sensors function correctly. Staying vigilant with calibration and maintenance keeps your system safe and efficient, avoiding costly failures and downtime.

Record Environmental Conditions

Maintaining accurate sensor performance over time requires more than regular calibration and maintenance; it also involves recording the environmental conditions in which your sensors operate. Proper environmental monitoring helps you identify factors like temperature fluctuations, humidity, and airflow that can affect sensor placement and reliability. Documenting these conditions allows you to spot patterns or changes that might compromise sensor accuracy. Keep detailed logs of environmental data alongside sensor performance records, especially during installation and after any adjustments. This practice ensures you understand how surroundings influence sensor function and can troubleshoot issues promptly. By tracking environmental conditions consistently, you improve your ability to maintain sensor integrity and ensure they provide reliable, timely alerts for tip over or overheat risks.

Train Personnel on Proper Sensor Handling and Response

Proper training is essential to guarantee personnel can effectively handle tip-over and overheat sensors. Well-trained staff understand sensor calibration processes and respond promptly to alarms. To achieve this:

- Educate on sensor calibration procedures to ensure accurate readings.

- Teach proper response protocols when sensors activate, minimizing downtime.

- Conduct hands-on personnel training to simulate real alarm scenarios.

- Reinforce the importance of regular maintenance and calibration checks.

Stay Updated on New Technologies and Standards

Staying current with new sensor technologies and industry standards guarantees your safety systems remain effective and compliant. Regularly review updates on sensor calibration methods and incorporate them into your maintenance routines to guarantee accuracy. As technology advances, newer sensors may offer improved reliability, so upgrading or recalibrating existing systems is essential. Keep track of industry standards issued by relevant authorities to ensure your safety protocols meet current requirements. Attending training sessions, reading industry publications, and participating in professional networks help you stay informed about innovations. By proactively incorporating the latest standards and sensor calibration techniques, you minimize risks of sensor failure, extend equipment lifespan, and maintain compliance, ultimately safeguarding your operations and personnel.

Frequently Asked Questions

What Are the Common Causes of False Triggers in Tip Over Sensors?

False triggers in tip over sensors often happen because of improper sensor calibration or environmental factors like vibrations or uneven surfaces. You should regularly check for sensor malfunction diagnosis and calibration issues, as these can cause false alarms. Additionally, dirt or debris can interfere with sensor accuracy, so keeping sensors clean helps. Addressing these issues guarantees your sensor functions correctly, minimizing false triggers and maintaining safety.

How Do Environmental Conditions Impact Overheat Sensor Accuracy?

Environmental influence can considerably impact overheat sensor accuracy. High humidity, dust, or extreme temperatures may cause false readings or delayed responses. To guarantee reliable performance, you need to regularly calibrate your sensors considering these conditions. Visualize your sensor as a thermometer; if the environment fluctuates wildly, calibration helps it interpret signals accurately, preventing unnecessary shutdowns or overlooked overheating issues. Proper calibration based on environmental conditions keeps your sensors precise.

Can Sensor Placement Vary Based on Different Equipment Types?

Yes, sensor placement can vary based on equipment types. You should carefully select sensor locations to guarantee accurate detection of tip overs or overheating. For different equipment, consider factors like size, shape, and typical heat sources or tipping points. Proper sensor placement minimizes false alarms and improves safety. Always follow manufacturer guidelines and adapt placement to specific equipment to maximize sensor effectiveness and ensure reliable operation.

What Maintenance Schedule Is Recommended for Sensor Systems?

You should calibrate your sensor systems regularly, ideally every 6 to 12 months, depending on usage and environment. Follow a maintenance checklist that includes inspecting sensor placement, cleaning sensor surfaces, testing functionality, and replacing worn parts. Proper calibration guarantees accurate readings, while routine maintenance prevents failures. Staying consistent with this schedule helps avoid unexpected sensor errors, keeping your equipment safe and running efficiently.

How Do I Upgrade Sensors Without Disrupting Safety Protocols?

Why settle for a sensor upgrade circus when you can do it right? You should carefully calibrate your sensors for peak performance and double-check upgrade compatibility before swapping out parts. To avoid safety protocol disruptions, plan the upgrade during scheduled maintenance, and test thoroughly afterward. This way, you keep safety intact, avoid surprises, and ensure your sensors stay sharp and reliable—no acrobatics required.

Conclusion

Mastering the mechanics of tip over and overheat sensors is manageable when you maintain meticulous monitoring and methodical maintenance. By properly placing, performing periodic tests, and promptly pinpointing problems, you’ll prevent false triggers and promote safety. Staying savvy with standards and training team members ensures seamless sensor success. So, stay vigilant, verify voltage, and value vigilant vigilance—because vigilant sensors keep your environment secure, sensible, and superbly safe.