To guarantee your tip-over and overheat sensors work properly, follow these seven rules: understand their basic function, regularly inspect and clean them, recognize signs of malfunction, install and place them correctly, use only compatible and quality replacement parts, keep firmware and software updated, and follow safety protocols during maintenance. Staying vigilant with these guidelines helps keep your appliances safe. If you keep these tips in mind, you’ll discover more tips to maintain ideal sensor performance.

Key Takeaways

- Proper calibration and system integration ensure sensors accurately detect hazards and activate safety measures promptly.

- Regular inspection and cleaning prevent sensor malfunctions caused by dirt, damage, or misalignment.

- Correct installation, placement, and using OEM parts are crucial for reliable tip-over and overheat detection.

- Firmware and software updates enhance sensor reliability, fix bugs, and improve overall safety features.

- Adhering to safety protocols during maintenance, including power disconnection and protective gear, is essential for safe troubleshooting.

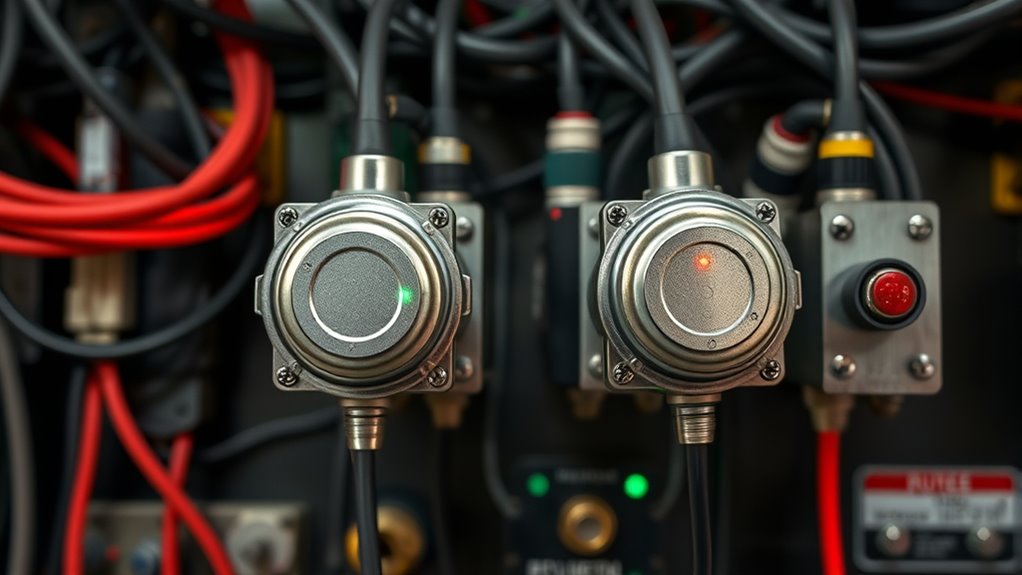

Understand the Basic Functionality of Tip Over and Overheat Sensors

Tip over and overheat sensors are essential safety devices designed to protect your appliances and environment. To ensure they work effectively, you need to understand their basic functionality. Sensor calibration is crucial; it fine-tunes each sensor to respond accurately to specific triggers, preventing false alarms or missed detections. Proper system integration guarantees that sensors communicate seamlessly with your appliance’s control system, enabling swift shutdowns when hazards occur. Once calibrated, these sensors detect unusual angles or high temperatures, activating safety measures instantly. Knowing how they operate helps you troubleshoot issues and maintain reliable protection. Additionally, understanding the contrast ratio can help you evaluate the overall performance of your home cinema setup, ensuring clear and vibrant visuals. Remember, well-calibrated sensors integrated properly form a vital line of defense, safeguarding both your home and the appliances you rely on daily.

Regular Inspection and Cleaning Are Key to Reliable Performance

Regular inspections and cleaning are essential to keep your sensors functioning properly. You should schedule routine checks, clean the sensors regularly, and look for any signs of damage. Staying proactive helps guarantee your safety systems work when you need them most. Additionally, understanding the legacy and importance of maintenance can help you appreciate why consistent care is vital for long-term reliability.

Schedule Routine Checks

To guarantee your tip over and overheat sensors work correctly, scheduling routine checks is essential. Regular inspections ensure sensors stay properly calibrated, maintaining accurate detection. You should test alarms periodically to confirm they activate promptly when needed. During each check, verify sensor calibration by following manufacturer instructions and adjust if necessary. Alarm testing involves simulating conditions that trigger the sensors to ensure they respond correctly, preventing false alarms or missed detections. Keep detailed records of each inspection and test to track performance over time. Consistent checks help identify potential issues early, reducing the risk of failure when you need the sensors most. Additionally, understanding the importance of regular maintenance can significantly extend the lifespan and effectiveness of your sensors. By staying proactive with scheduled inspections, you enhance safety and reliability without surprises.

Keep Sensors Clean

Keeping sensors clean is vital for guaranteeing they function accurately and reliably. Dirt, dust, or debris can interfere with sensor calibration, leading to false readings or missed signals. Regular inspection helps you spot buildup caused by environmental factors like humidity or airborne particles. Clean sensors gently with a soft cloth or compressed air, avoiding harsh chemicals that might damage sensitive components. By maintaining cleanliness, you reduce the risk of sensor malfunction and improve overall safety. Remember, a clean sensor provides more consistent and trustworthy data, which is essential for proper tip-over and overheat detection. Incorporating routine cleaning into your maintenance schedule can help prevent sensor corrosion and ensure they respond correctly when needed most.

Monitor for Damage

How can you guarantee your sensors remain reliable? Regularly inspecting them for damage is essential. Look for cracks, corrosion, or loose connections that could impair sensor calibration. Damaged sensors might not trigger alarms at the correct alarm thresholds, risking safety. Ensure wiring is intact and the sensor housing isn’t compromised. Keep an eye on any unusual signs of wear or debris that could interfere with proper functioning. If you notice discrepancies in sensor readings, recalibrate immediately to maintain accurate performance. Regular inspection also helps identify potential issues before they escalate. Understanding industry trends aids in staying updated on the latest sensor innovations and best practices. Remember, consistent maintenance keeps your tip-over and overheat sensors operating as intended, reducing false alarms and ensuring safety when it matters most.

Recognize and Address Common Signs of Sensor Malfunction

Sensor malfunctions often show themselves through clear and noticeable signs. If your tip over or overheat sensors malfunction, you might notice false alarms or no alarms at all. To address this, regularly check for calibration issues. Poor sensor calibration can cause inaccurate readings, making alarms unreliable. Additionally, if the alarm calibration isn’t correct, the sensor might trigger unnecessarily or fail to activate when needed. Ensuring proper sensor placement can also prevent many common issues. Look out for these signs: – Frequent false alarms or no alarms when there should be – Inconsistent or drifting sensor readings – Visible damage or dirt obstructing the sensor’s view If you observe these signs, recalibrate your sensors promptly. Proper sensor calibration ensures accurate detection and reliable safety alerts, preventing potential hazards.

Proper Installation and Placement to Prevent False Alarms

Proper installation and placement of tip over and overheat sensors are essential for reliable operation. Accurate sensor calibration ensures the device detects genuine issues without false alarms, so follow the manufacturer’s instructions carefully. Placement accuracy is equally critical; position sensors where they can effectively monitor potential hazards without interference from nearby objects or heat sources. Avoid mounting sensors too close to vents, fans, or heat-producing appliances, which can trigger false alarms. Ensure they are securely mounted at recommended heights and angles to maintain consistent readings. Regularly check the placement over time, especially after renovations or rearrangements. Incorporating proper placement techniques can significantly improve sensor performance and reduce false alarms. Proper installation and precise placement help these sensors function correctly, reducing false alarms and ensuring prompt alerts when genuine issues occur.

Use Compatible and Quality Replacement Parts

Using compatible and high-quality replacement parts is essential to guarantee your tip over and overheat sensors function reliably and safely. When selecting replacements, verify they match the original specifications to maintain proper sensor calibration. This helps avoid false alarms or missed detections. High-quality parts also tend to last longer and are less prone to failure, reducing the need for frequent replacements. Follow proper replacement procedures, such as disconnecting power before installing new components and verifying connections. To optimize performance, always double-check compatibility with your device model. Consider these tips:

- Choose OEM or certified parts to ensure compatibility

- Confirm the replacement parts meet safety standards

- Perform sensor calibration after installation for accurate readings

- Recognize that trust issues within relationships can impact how you perceive and respond to equipment failures, highlighting the importance of thorough checks and reliable parts.

Keep Firmware and Software Updated When Applicable

Have you checked if your appliance’s firmware or software is current? Keeping firmware updates up to date ensures your device functions properly and security vulnerabilities are patched. Manufacturers often release software patches to fix bugs, improve performance, and enhance safety features, including tip over and overheat sensors. Regularly updating firmware can prevent false alarms or missed detections, reducing the risk of accidents. To do this, visit the manufacturer’s website or use the device’s app to check for updates. Install firmware updates promptly and verify that your software is running the latest version. Staying up to date helps maintain the reliability of safety sensors and ensures your appliance operates as intended, providing peace of mind and reducing potential hazards.

Follow Safety Protocols During Troubleshooting and Maintenance

Because troubleshooting and maintenance can expose you to electrical hazards or moving parts, it’s essential to follow safety protocols every time you work on your appliance. Always disconnect the power before starting repairs, and verify that the appliance is unplugged. Keep a fire safety kit nearby in case of electrical sparks or overheating. Remember to follow emergency protocols—know how to shut off power quickly and contact emergency services if needed. To stay safe, adhere to safety measures such as wearing insulated gloves and eye protection. Additionally, implementing automated safety systems can provide real-time alerts to prevent accidents. Keep a fire extinguisher nearby for emergencies. Adhering to these safety measures minimizes risks during troubleshooting. Prioritize fire safety, stay alert for hazards, and never bypass safety procedures to ensure your safety and proper appliance maintenance.

Frequently Asked Questions

How Often Should Sensors Be Tested for Accuracy?

You should test your sensors for accuracy at least once every six months as part of your maintenance schedule. Regular sensor calibration guarantees they function correctly and helps prevent false alerts or failures. Keep a record of these tests and calibration dates, and immediately address any discrepancies. Consistent testing maintains safety and reliability, so don’t skip this essential step in your maintenance routine.

Can Environmental Factors Affect Sensor Performance?

Environmental hazards like extreme temperatures can definitely impact sensor performance. For example, if you place a tip-over sensor near a heat source, it may falsely trigger or fail to activate when needed. Proper sensor placement is essential to avoid such issues, ensuring they aren’t exposed to moisture, heat, or vibrations. Regularly evaluating environmental conditions helps maintain sensor accuracy and reliable safety alerts.

What Are the Cost Implications of Sensor Replacements?

Replacing sensors can be costly, depending on their lifespan and the type you need. You might face significant replacement costs if sensors fail prematurely due to environmental damage or frequent use. To minimize expenses, regularly maintain and monitor sensor performance, and consider investing in high-quality sensors that offer longer lifespans. Doing so helps reduce frequent replacements, lowering overall costs and ensuring reliable safety features.

Are There Specific Brands Recommended for Replacements?

You should prioritize brands known for sensor durability and brand reliability when choosing replacements. Look for reputable manufacturers like Honeywell, Siemens, or Schneider Electric, as they tend to produce sensors with longer-lasting performance and fewer failures. Investing in trusted brands might be slightly more expensive upfront, but it saves you money in the long run by reducing maintenance costs and ensuring consistent safety and functionality.

How Do I Troubleshoot False Alarms Caused by External Interference?

Imagine a quiet room suddenly disrupted by a false alarm, caused by external interference. To troubleshoot, first identify nearby devices like radios or wireless signals that might be causing the issue. Move the sensor away from these sources, and make certain all connections are secure. If false alarms persist, consider shielding the sensor or updating its firmware. These steps help minimize external interference and keep false alarms at bay.

Conclusion

By following these rules, you’ll create a safety net around your device, much like a guardian angel watching over delicate flames and sensitive sensors. Imagine a clear sky after a storm—calm, bright, and free of hidden threats. Regular checks and proper care keep your sensors functioning smoothly, preventing chaos and ensuring peace of mind. Stay vigilant, stay protected, and let your equipment operate seamlessly like a well-orchestrated symphony.